5S approach: from Japan to Rocchetta, the Marche plant pioneers this new method

Seiri, Seiton, Seiso, Seiketsu, Shitsuke: these 5 words (‘5S’ words) stand for the pillars of a Japan-based approach focused on reducing redundancy and tidiness to optimise the organisation of workspaces in manufacturing plants and maintain a safe and efficient work environment.

Since a little over a year, the 5S approach has also been applied in the plant in Rocchetta, part of the Fabriano paper mill (Fedrigoni Group) handling the cutting of paper, delivered here in large reels to be transformed into small A4 and A3 reams, according to customer requirements.

Mauro Chiucchi was Plant Manager until 30 March 2023 for the Rocchetta plant and is the person who successfully fostered the use of the 5S method. Rocchetta is now the ‘pilot’ plant, to test its feasibility and looking ahead to future application in other Group plants.

“Our priority is to ensure safe and healthy working conditions at the plant; implementing the 5S method will further improve our working environment. How? On two sides: work environment and the implementation of new approaches” Chiucchi said.

“The first challenge was to overcome the early scepticism among colleagues: I was told this method could not apply here. Of course there can be different standpoints when the way of working is questioned, yet little by little, we managed to convince everyone it could be done. Many became enthusiastic, and today everyone is aware of improvements for their own well-being.”

How exactly does the 5S methodology work?

We explain this by referring to how it was realised in Rocchetta, plant with facilities for cutting more than 500 tonnes of paper per day.

There was first of all a planning phase involving a specialised external consultant, a project manager and other in-house players who followed all the stages to acquire the know-how, gradually becoming experts in the methodology. Some 80 people were then involved in the work teams in different stages, called upon to learn the techniques and implement the activities as specified.

Once the teams have been defined, the area of the plant is divided into intervention areas, where work begins, a little at a time, as follows:

1 S (Seiri) sort, the necessary from the unnecessary, i.e. all the material that may be lying there but is not necessary, or is only temporarily or periodically required, is assessed and taken out, in a specific “red-tag area”;

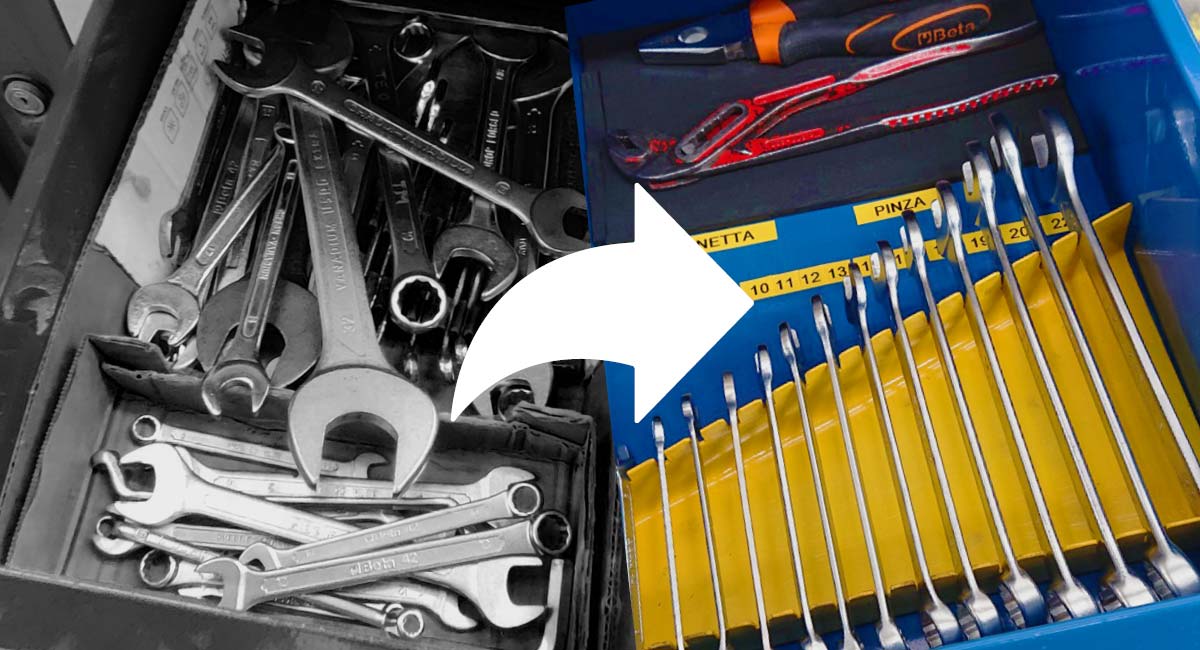

2 S (Seiton) set in order, “a place for everything and everything in its place”, i.e. the materials that had been taken out are smartly kept organised in such an order as to have them at hand when needed, reducing the time spent on looking for them;

3 S (Seiso) shine and inspect the work area, and perform small interventions on the machines, checking whether the equipment is tidy;

4 S (Seiketsu) standardize, once the first three “S” have been implemented, rules are set on how and when tasks are to be performed. These standards may include schedules of the cleaning areas and the organisation of spaces;

5 S (Shitsuke) sustain, regular reviews are to be made to monitor the level achieved and to implement any improvements.

“The most difficult ‘S’s’ are the last two, especially the keeping in time, but I must admit there has been a lot of co-operation from colleagues, since the benefits were immediately perceived. The work environment is tidier and cleaner, so working is more fulfilling and less stressful for people. A benefit in terms of well-being, as well as greater job safety. Free space is made available, removing redundant items, transitions are better and no materials get in the way, people stand better at their workstations and have their tools at hand. Besides, this approach feeds into teamwork and methodical approach”.

The project is being implemented over two years, a time frame deemed most suitable for people to acquire and become familiar with the method, turning it into the “standard” way to work. “Setting this project up too quickly can make it fail. If people feel involved and empowered, with the right timeframe, they work together for a common purpose whose benefit can be clearly experienced. Together with the team, they are those who ultimately decide what should be done to improve a specific area and spaces, nothing is “dropped from above”, they are those who take the decisions, respecting the rules. The 5S projects belong to those who run them”.

Find out more about the 5S method in the special Bits on Sustainability